The two-part system consisting of a custom-fit refurbishment plate.

- The plate is centrically arranged over the existing rainwater outlet and flashed against the existing waterproofing without backflow.

- The drainage element itself is then simply inserted into the refurbishment plate.

- Flashing against the new waterproofing is carried out either with connecting flange and screw ring (refurbishment rainwater outlet 125) or with factory fitted connecting flange (refurbishment rainwater outlet 75, 110).

Refurbishment Outlets

In the case of refurbishment with additional thermal insulation, where it is not possible to replace existing outlets, it is recommended to install alwitra® refurbishment rainwater outlets.

40 years experience with waterproofing systems in the UK

As used on landmark architecture throughout the world

Applications

- Refurbishment projects with the additional thermal insullation

Product Details Back to top

Product Specification

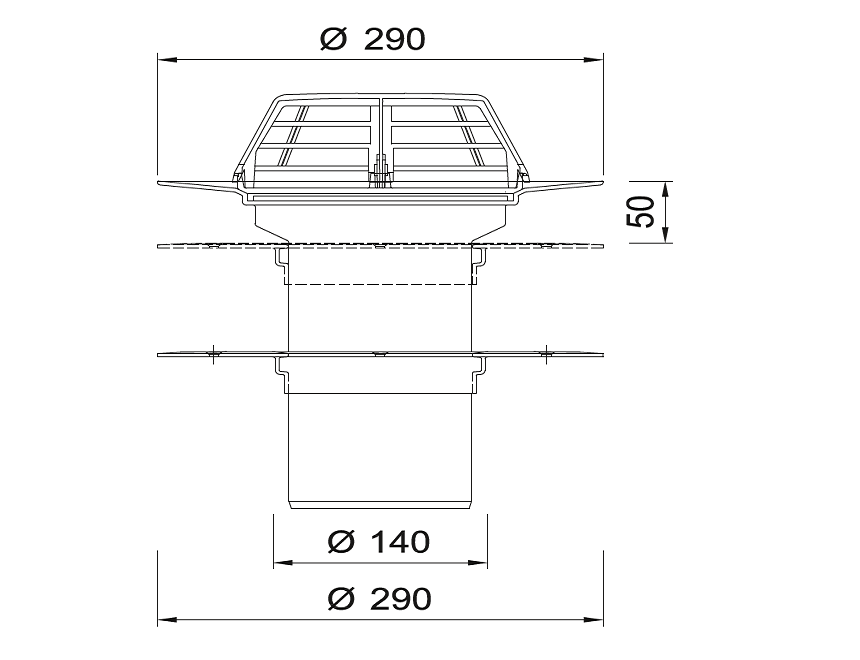

Technical data for alwitra® refurbishment rainwater Outlet 125

|

For existing rainwater outlets: |

DN 125 - DN 150 |

| Material: | highly impact resistant PP |

| Min. thickness of additional insulation: | approx. 50 mm |

| Max. thickness of additional insulation: | approx. 200 mm |

| Outer diameter of flange: | 290 mm |

| Flange width: | approx.50 mm |

| Diameter of the drainage element: | approx. 120 mm |

| Outer diameter of connecting flange: | 480 mm |

| Refurbishment plate: | PP black |

Technical Data for alwitra® refurbishment rainwater outlet 75 and 110

|

For existing rainwater outlets: |

DN 100 (outlet 110) DN 70 - DN 90 (outlet 75) |

| Material: | PVC |

| Min. thickness of additional insulation: | approx. 10 mm |

| Max. thickness of additional insulation: | approx. 300 mm |

| Connecting flange: | factory-fitted, in the colour of the waterproofing membrane 75: 180 x 180 mm 110: 230 x 230 mm |

| Refurbishment plate: | Aluminium |

Technical Drawings